This adjustable gas system is installed directly on the gas tube. It provides positive indexing of the adjustment screw for precise and repeatable gas settings for semi-auto AR platform rifles.

The system is especially recommended for rifles that become over-gassed when a suppressor is installed. Many standard AR gas systems are not designed to handle suppressor backpressure, which results in excessive gas drive, increases rearward bolt-carrier velocity, and causes additional rifle shake during the firing cycle, ultimately reducing precision. Proper gas regulation directly affects shot consistency and overall accuracy.

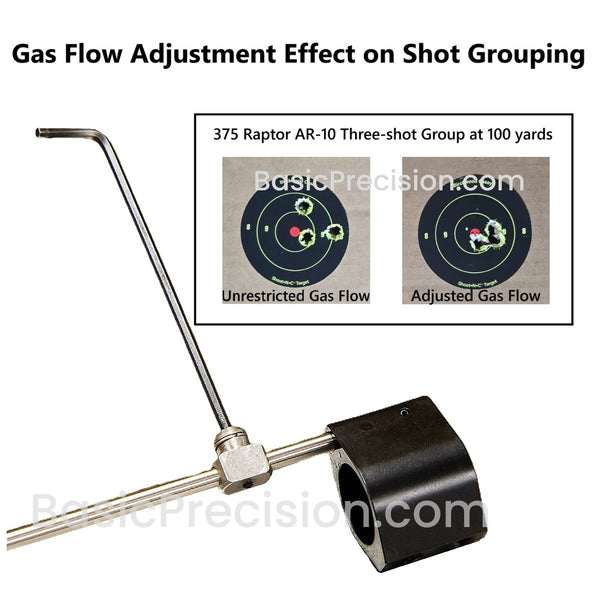

The system allows the gas flow to be tuned to the minimum amount required for reliable cycling. The adjustment process is simple: close the valve one click at a time until the rifle no longer cycles, then open it one click back. This delivers only the necessary gas flow to the bolt carrier, reducing excess carrier speed and minimizing unwanted barrel disturbance. In practice, this results in tighter shot groups. Depending on rifle configuration and ammunition, typical improvement in group size can range from 0.25 MOA to 0.75 MOA. The image below shows actual results from a Basic Precision range test demonstrating the system’s influence on precision:

This adjustable gas system is also ideal when a low-profile gas block solution is required.

All components are CNC-machined from stainless steel, eliminating corrosion and stripped adjustment screws common with conventional designs.

Configuration Options

- Available lengths: pistol, carbine, mid-length, rifle-length, rifle-length plus 2 inches, or custom length

- Available as:

- Adjustment valve only

- Gas tube with adjustment valve installed

- Gas tube with adjustment valve and low-profile steel gas block with NitroMet finish

Installation Note

If your rifle's design allows the adjustment valve to be installed in front of the handguard, no modification is necessary. If not, a minor modification of the handguard may be required to access the valve. This may involve either cutting a small access slot or drilling an access hole, as shown in the images below. This allows adjustment of the gas valve without removing the handguard.